Ferromanganese 75%

Fe–Mn master alloy (~75% Mn) used as a deoxidizer and alloying addition in steelmaking to control sulfur and improve strength and toughness.

Browse refractory materials and chemical products.

Fe–Mn master alloy (~75% Mn) used as a deoxidizer and alloying addition in steelmaking to control sulfur and improve strength and toughness.

High-purity SiC grains for refractories, kiln furniture, and metallurgical additives; noted for high hardness, thermal conductivity, and thermal-shock resistanc…

Electro-fused alpha-Al2O3 with high hardness and chemical stability; used in high-alumina castables, bricks, and precision blasting/polishing media.

Sized WFA aggregate (1–3 mm) for refractory castables and monolithics to provide strength, abrasion resistance, and corrosion resistance.

Fused zirconia-toughened mullite grains offering excellent thermal-shock and slag resistance; used in high-duty refractories and kiln furniture.

Fine-sized ZrO2-mullite grains (0.5–1 mm) for dense, tough refractory mixes requiring enhanced creep and corrosion resistance.

Fused calcium aluminate flux/binder for steel refining and castables; promotes desulfurization and provides rapid hardening in refractory systems.

Fused MgO-Cr2O3 grains (0–1 mm) used in high-temperature refractories for slag resistance and structural integrity in basic environments.

High-purity fused magnesia grains (0–5 mm) with excellent basicity and refractoriness; widely used in basic bricks and castables.

Carbonaceous material calcined to increase density and conductivity; used for carbon additives, anodes, and carburizing in foundry/steel.

Sized CPC (2–8 mm) for controlled addition as carburizer and in carbon-based refractory mixes requiring high carbon yield.

Polymeric or mineral fibers dispersed in concrete/refractory mixes to relieve vapor pressure and reduce spalling risk under rapid heating.

Thermosetting binder for shaped and monolithic refractories; provides green strength and cokes to a carbon matrix on curing/pyrolysis.

Fe–Si alloy with controlled impurities for deoxidation, alloying, and inoculation in steel and foundry applications.

Intercalated graphite that expands upon heating to form an intumescent, insulating layer; used in fire protection and sealing systems.

MgFe2O4 spinel-type material used as a refractory component and ceramic pigment; offers thermal stability and chemical resistance.

Al2O3-rich refractory bricks with good hot strength and corrosion resistance; widely used in kilns, furnaces, and ladles.

Cr2O3-containing corundum refractory offering enhanced slag and wear resistance for severe service zones.

Fe–Cr master alloy used to produce stainless and alloy steels by supplying chromium for corrosion and wear resistance.

Si–Ba alloying/deoxidizing agent that promotes desulfurization and improves castability and microstructure in steel.

Si–Ca deoxidizer/desulfurizer used in steel refining and as a nodulizer support in foundry iron.

Si–Ca–Ba additive combining strong deoxidation with improved inclusion modification and fluidity in steelmaking.

Si–Mn alloy used widely as a deoxidizer and alloying agent to improve strength and hardenability in steels.

High-alumina silicate bricks designed for general furnace linings where refractoriness and load-bearing are required.

SiO2-rich refractory with excellent load-softening at high temperature; used in coke ovens, glass tanks, and hot blast stoves.

Black SiC abrasives and refractory grains offering high hardness and wear resistance with good thermal shock behavior.

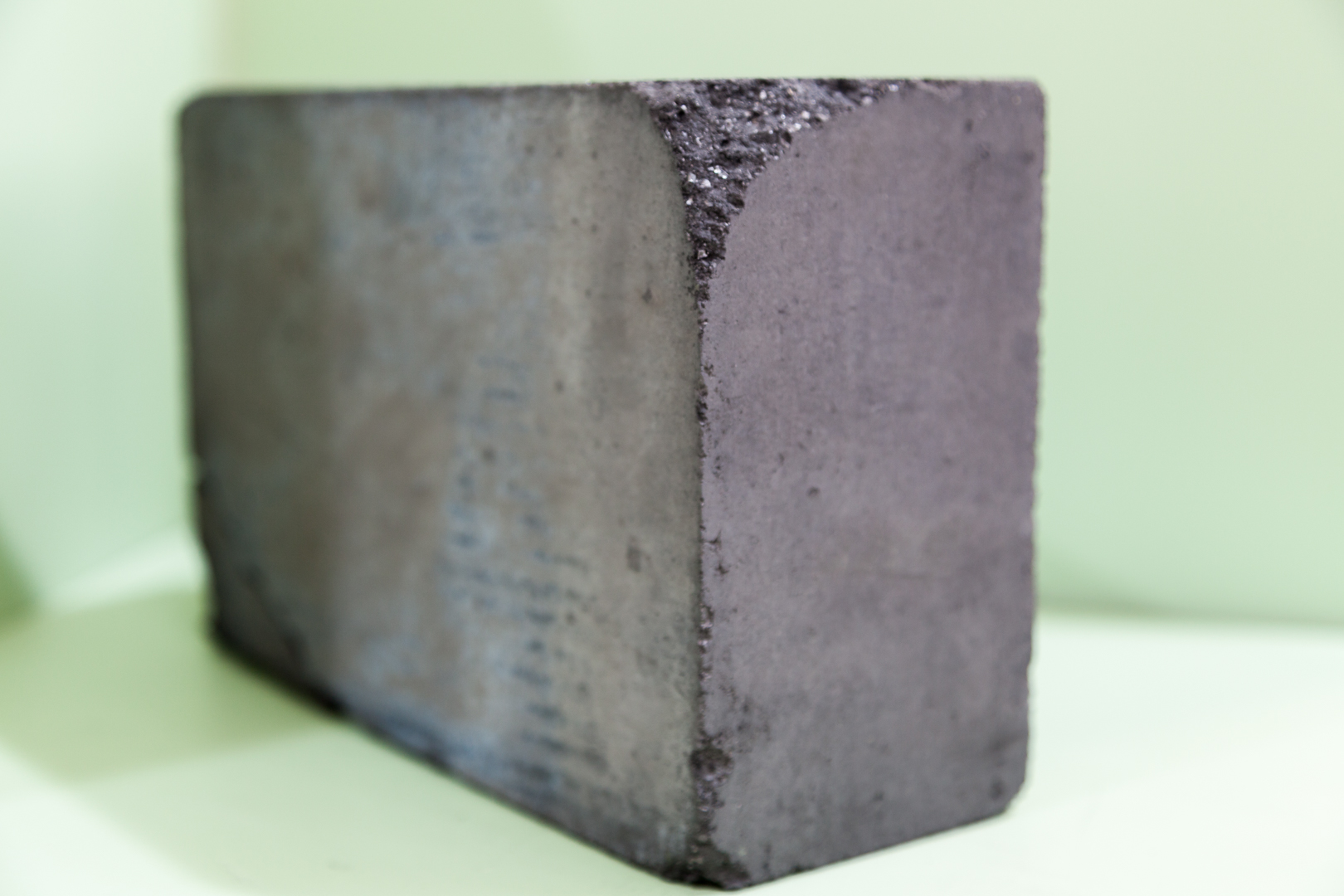

AMC bricks combining Al2O3, MgO, and carbon for superior slag resistance and thermal shock performance in steel ladles and converters.

Grain mix of MgO and chromite for making basic refractories with good corrosion resistance to slags.

Basic bricks based on MgO-Cr2O3 with strong resistance to basic slags and high-temperature structural stability.

Synthetic or fused MgAl2O4 spinel used to enhance thermal-shock and corrosion resistance in alumina-based refractories.

Calcined kaolinitic clay (mullitic after firing) used as a reactive alumino-silicate filler for castables and plastics.

Fe–Mo master alloy for alloy steels and stainless; improves strength, creep resistance, and corrosion performance.

High-temperature cement (typically calcium aluminate based) used as binder in castables and for hot-strength mortar joints.

Fe–B master alloy for grain refinement, hardenability, and wear resistance in specialty steels and foundry alloys.

Rigidized alumino-silicate fiber panels offering low thermal conductivity and lightweight lining for furnaces and ducts.

Fe–Ti master alloy for deoxidation and inclusion control; also used to introduce Ti for grain refinement in steels.

Rigid insulation boards with low thermal conductivity and good machinability for industrial thermal barriers.

Zirconia powders or grains used for toughened ceramics and refractories; noted for high melting point and chemical resistance.

Cr2O3 green pigment with excellent heat and chemical stability; also used as an additive in refractories and ceramics.

Lightweight, closed-cell alumina spheres offering low bulk density, high refractoriness, and thermal-shock resistance.

Insulating bricks made from alumina hollow spheres for high-temperature linings where low heat storage and strength are both needed.

Carbon additive for adjusting carbon content in molten iron/steel; selected for high fixed carbon and low impurities.

Surface-active agent used to improve wetting and penetration in coatings, foundry washes, or cleaning processes.

Carbon-rich solid from delayed coking; used as fuel, carbon additive, and in anode/cathode materials where permitted.

Fine carbon particulate used as reinforcing filler, pigment, and conductive additive in polymers and refractories.

SiC–Fe additive powder used in foundries and steelmaking for deoxidation, carburization support, and to refine microstructure.

Natural alumino-silicate mineral that converts to mullite on firing; valued for low thermal expansion and thermal-shock resistance.

Siliceous frustules of diatoms forming a lightweight, porous powder used for filtration and as thermal insulation filler.

Expanded micaceous mineral providing lightweight insulation and improved thermal shock resistance in refractory mixes.

Chamotte (calcined fireclay) used as grog/aggregate to impart thermal stability and reduce shrinkage in refractories.

Chamotte aggregate of a different grade/size, providing skeleton structure and crack resistance to refractory bodies.

Natural graphite flakes with high lubricity and thermal conductivity; used in carbon refractories and gaskets.

Natural MgCO3 source for magnesia production; used to make basic refractories after calcination/sintering.

FeS additive used in metallurgy and certain chemical processes; handled with care due to sulfur content.

Alumina-rich ore for high-alumina refractories and alumina production; provides fire resistance and strength after calcination.

Sized bauxite aggregate (5–8 mm) for castables and brick mixes where controlled grading is required.

Thermally treated aluminum powder for use in metallurgical and refractory systems requiring reactive alumina sources.

Low-expansion, high-purity SiO2 used where thermal shock resistance and dimensional stability are critical.

Amorphous graphite with fine lamellar structure used as lubricant, pigment, and carbon source in refractories.

Expanded volcanic glass granules providing lightweight thermal insulation and reduced thermal mass.

Finer perlite grade for uniform packing and improved insulation in lightweight mixes and boards.

BaSO4 mineral powder valued for high density and chemical inertness; used as filler and weight material.

Sintered MgO with high density and refractoriness; key raw material for basic bricks and monolithics.

Lightweight AAC blocks with closed-cell structure providing thermal insulation and ease of machining for non-load-bearing walls.